Features

Consistent cut quality, regardless of operator

As a superintendent/greenkeeper, turf manager, equipment manager, or other supervisor responsible for golf course maintenance, there are many aspects you are judged on every single day. Some that stand out include:

- Quality of turf and overall playing conditions

- Consistency from hole to hole (or area to area)

Golfers expect the highest level of playing conditions every time they play, and they expect hole #1 to play the same as hole #18. Over the years, those demands have increased as they continue to see picturesque tournaments on television.

However, one of the toughest challenges in the industry today is labor. With unemployment rates at very low levels and wages increasing, it is difficult to find labor, and when you do find it, it’s often unskilled. Skilled, experienced operators can typically provide the daily quality that you are seeking. However, how do you take those new, less-skilled operators and make them perform like a 20-year veteran? For some, they may have never worked on a golf course before or may have limited general equipment operating experience.

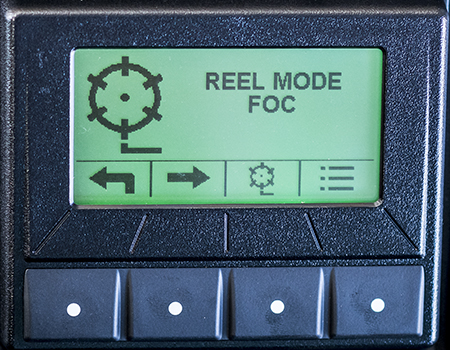

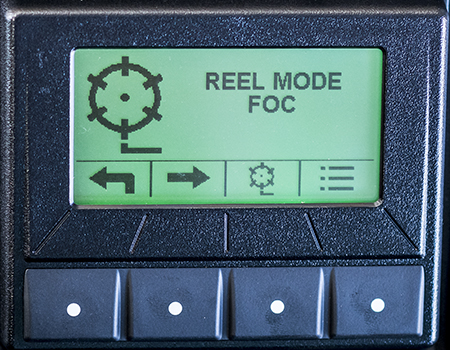

Operator view of TechControl display

Operator view of TechControl display

Passcode protection within TechControl

Passcode protection within TechControl

That’s where the 2700 and 2750 PrecisionCut™ and E-Cut™ Hybrid Triplex Mowers can to help. The key is the advanced TechControl display, which allows you to enter a multitude of operating parameters to gain more control over your operators’ performance. In addition, the TechControl display is passcode protected, meaning that operators cannot do anything to override the settings that you have programmed without having the passcode. The operator can see limited information to operate the machine, such as:

- Operating mode (park, transport, mow)

- Fuel level

- Hour meter

- Warning indicators/alarms

No matter how many machines you have, if you set them all up the same, they will all perform the same regardless of operator.

Increased level of supervisory control with advanced passcode-protected TechControl display

As a turf professional responsible for your course, there’s a certain level of care you would take if you were operating a triplex mower yourself. The advanced TechControl display on the 2700 and 2750 PrecisionCut™ and E-Cut™ Hybrid Triplex Mowers allows you to build a similar level of care into how your operators are allowed to mow. It also allows newer operators to match the cut quality and consistency of veteran operators by putting you in control of key performance characteristics.

Advanced TechControl display

Advanced TechControl display

TechControl display location

TechControl display location

As a trusted supervisor, the passcode-protected TechControl display allows you to control a range of operating parameters, including:

- Reel operating modes

- Frequency of clip

- Engine operating modes

- Maximum mowing speed

- Cruise control

- LoadMatch™ speed setting

- Turn speed

- Maximum transport speed

- Cleanup pass speed

- Cutting unit lift rates

- Cutting unit drop rates

- Cutting unit front-to-rear timing

By giving you control of the operating parameters that operators must stay within, the result is better, more consistent cut quality and overall playing conditions. In addition, you get improved consistency from hole to hole, regardless of which operator is operating the machine. The passcode protection helps prevent operators from overriding any of the parameters that have been set, giving you more control over the performance of each operator.

Walk Greens Mower-like cut quality with frequency of clip control

For many years, John Deere fixed-head walk greens mowers have featured automatic frequency of clip control. Due to the chain drive system linking the traction drum to the reel, the same frequency of clip is maintained at all ranges of the engine throttle. At higher engine speeds, the reel speeds up in proportion to the increased speed of the traction drum. At lower engine speeds, the reel slows down in proportion to the traction drum. What this means is the same frequency of clip is maintained from machine to machine and operator to operator, regardless of the engine throttle position.

With labor availability becoming more of a challenge, recent industry trends show more courses going back to triplex mowers on greens to increase productivity.

But can a triplex match the cut quality of a walk behind? With the Frequency of Clip mode within the TechControl display on all 2700 and 2750 PrecisionCut™ and E-Cut™ Hybrid Triplex Mowers, that level of cut quality can be achieved regardless of the operator. In fact, the 2700 and 2750 PrecisionCut Triplex Mowers are the only hydraulic reel drive triplex mowers in the industry that can control frequency of clip.

Frequency of Clip mode

Frequency of Clip mode

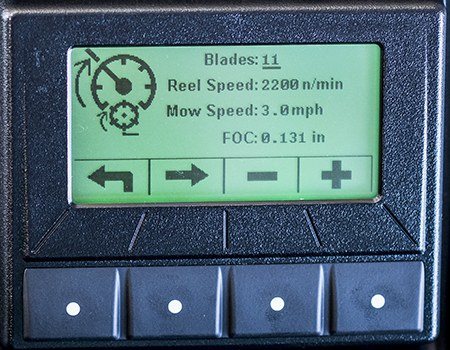

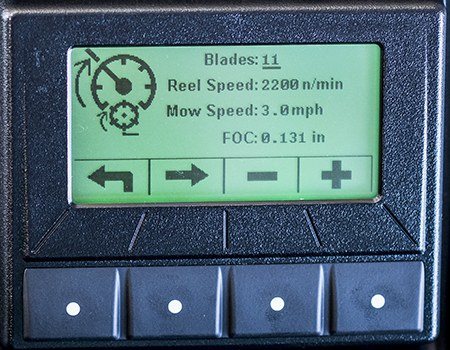

Frequency of Clip setup screen

Frequency of Clip setup screen

Within the passcode-protected TechControl display, the supervisor has the ability to select Frequency of Clip mode. After pressing the menu button, the supervisor enters the following parameters:

- Number of blades on the reel

- Reel speed

- Mow speed

Based on these parameters, the machine will calculate and display the frequency of clip that the machine will target to achieve. If there is a certain frequency of clip you desire, simply change the mow and reel speeds to find that setting. Or, you may decide that a different reel blade count is required to get the frequency of clip that you want to achieve. Once you exit the setup screen, the parameters are set for the operator to mow.

The mow speed that is set is the maximum mowing speed that the operator can mow at. A veteran operator may choose to mow at the maximum mowing speed, while a newly trained operator may elect to mow slower by not fully depressing the pedal.

However, the frequency of clip does not change on the 2700 and 2750 Triplex Mowers based on these different mowing speeds. It is maintained regardless of ground speed. The reel speed automatically adjusts to the requested ground speed from the foot pedal. Even though a newly trained operator may mow at a reduced speed, the reels slow down automatically in proportion to maintain the same frequency of clip as an experienced operator. This means consistent cut quality from hole to hole all day long, regardless of the operator.

For all 2700 and 2750 PrecisionCut and E-Cut Hybrid Triplex Mowers, the reel speed sensor and foot pedal position sensor communicate with one another to maintain frequency of clip. The foot pedal position sensor indicates the requested ground speed from the operator, and the reel speed automatically adjusts accordingly. Wheel speed sensors in the hydraulic wheel motors communicate with the eHydro™ system to match the actual ground speed to the requested ground speed.

Budget and operator-friendly Eco mode

Within the advanced TechControl display, you can run the engine in Eco mode for general mowing conditions, especially on greens. In Eco mode, the engine will run at 2250 rpm with the power take-off (PTO) engaged. As load demand increases due to conditions such as lush grass or climbing a hill, the engine speed can increase to as much as 2700 rpm. It all happens automatically without any operator input other than engaging the mow switch.

Eco mode in the TechControl display

Eco mode in the TechControl display

A passcode must be entered to select the engine mode that you want the operator to use. Once Eco mode has been selected, there is nothing the operator needs to do to activate it. Also, there is nothing the operator can do to mow outside of Eco mode. Once the mow switch is engaged, the engine will automatically go to 2250 rpm. As additional load is encountered, the engine rpm will automatically increase without any input from the operator.

Eco mode is friendly to the operating budget, as well as the operator. In this mode, you will see up to 30 percent reduction in fuel consumption, and up to a 5 dB(A) reduction in sound levels (depending on the model). It also works across all 2700 and 2750 PrecisionCut™ and E-Cut™ Hybrid Triplex Mowers. Fuel savings and noise reduction are no longer reserved for hybrid machines.

Some of the highest load conditions are cold mornings where the hydraulic oil has not yet come up to operating temperature. In these conditions, the hydraulic oil temperature sensor integrates with Eco mode to ensure there is power available to handle the task. This smart system will quickly bring the oil up to operating temperature by:

- Increasing engine rpm to 3000

- Shutting off diverter valve

- Shutting off engine cooling fan

As the oil reaches certain temperature thresholds, the diverter valve will be enabled, the cooling fan will be turned back on, and the engine will return to normal Eco speed (2250 rpm). Normal Eco operation will resume once the hydraulic tank temperature is 50°C (122°F).

Excellent cut quality in undulations and perimeters using three-axis contour following system

Triplex mowers are some of the most versatile reel mowers around and mow in a wide variety of applications where quality of cut on contours can be a challenge, including:

- Greens

- Tees

- Fairways

- Approaches

- Surrounds

In these challenging conditions, a triplex mower must be able to handle not only the upward and downward contours, but also side-to-side rolling terrain and perimeter cuts. Contour following is an area where the 2700 and 2750 PrecisionCut™ and E-Cut™ Hybrid Triplex Mowers truly excel.

With its innovative three-axis lift system, the 2700 and 2750 Triplex Mowers are packed full of contour following capability, including:

- 42 degrees of upward and downward movement (21 degrees upward, 21 degrees downward)

- 36 degrees of lateral roll movement (18 degrees each direction)

- 36 degrees of front cutting unit steering (18 degrees each direction)

- 17 degrees of rear cutting unit steering (8.5 degrees each direction)

All of this built-in capability ensures excellent cut quality on tough contours and tight perimeters.

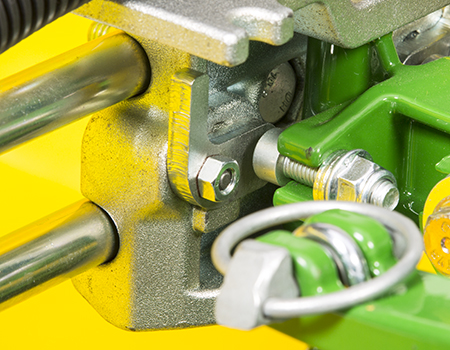

Cutting unit contour following system

Cutting unit contour following system

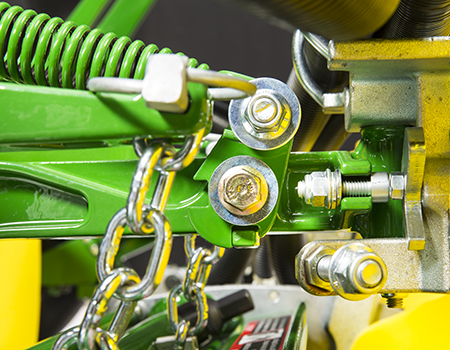

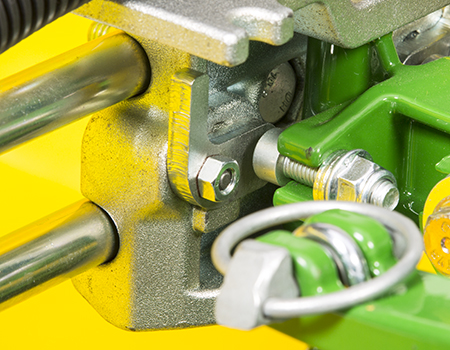

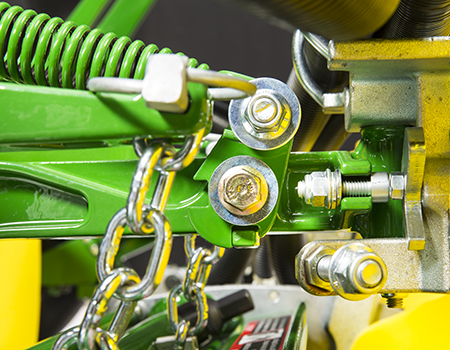

The system consists of a series of ball joints, sealed bearings, and non-metallic bushings, providing excellent reliability and durability. Best of all, the system is completely maintenance free with zero grease points. There are three independent lift cylinders, and the lift/lower valve goes into float when the cutting units are lowered to allow for the contour following system to do its job.

Weight transfer spring

Weight transfer spring

Spring in forward position

Spring in forward position

Spring in rearward position

Spring in rearward position

An integrated weight transfer spring for each cutting unit helps transfer weight from the cutting unit to the traction unit. These springs do an excellent job in minimizing opportunities for marking and step cutting in turns, providing a high level of cut quality in perimeters. There are two operating positions for this spring: a forward position and a rearward position. In most conditions and applications, the spring will be operated in the forward position. This will transfer approximately 18 kg (40 lb) from the cutting unit onto the traction unit. In more aggressive undulations where quicker contour following response is needed, the rearward position can be used, which reduces the weight transfer by 4.5 kg (10 lb).

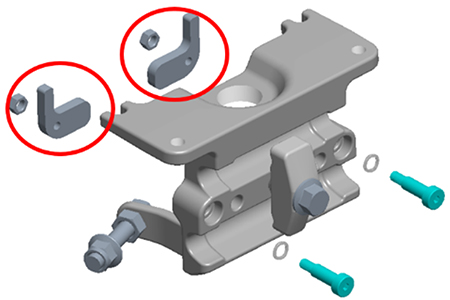

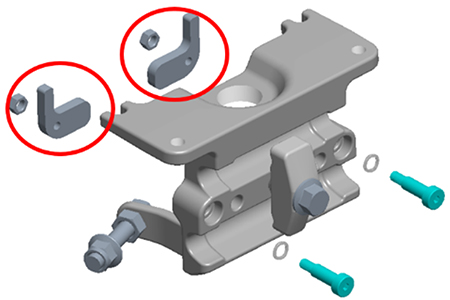

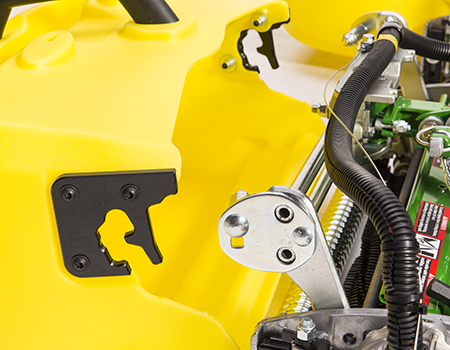

Cutting unit steering limiters

Cutting unit steering limiters

The 18 degrees of steering is very important, especially on greens, for maintaining high levels of cut quality in turns and in perimeter passes. The system allows the cutting units to steer as the machine steers, helping to minimize opportunities for scalping while maintaining a consistent height of cut. In combination with the weight transfer springs, the steering system helps provide consistent quality of cut with less opportunities for marking and step cutting in cleanup passes.

Steering limiters disengaged

Steering limiters disengaged

Steering limiters engaged

Steering limiters engaged

However, there are some situations where you may not want as much cutting unit steering, such as highly undulating terrain in fairways, surrounds, and approaches. The standard cutting unit steering limiters provide the capability for the supervisor to lock out the cutting unit steering system to reduce the opportunity for uncut strips. This system provides flexibility to limit steering both in the inward and outward directions independently. With the limiters on both sides disengaged, they allow for full steering of the cutting unit. When engaged on the front cutting units (as shown), steering is limited to 9 degrees, or in combination with moving two washers, steering can be completely locked out to 0 degrees. Engaging the steering limiters on the rear cutting unit completely locks out the steering to 0 degrees.

A dual chain attaching system makes sure the cutting unit is square to the turf at all times during the lift and lower cycle and helps to maintain cutting unit stability when mowing hillsides. This can minimize any potential marking on cutting unit drop. The patented position of the lateral roll axis of the contour following system is close to the center of gravity of the cutting unit, keeping the cutting units very stable in transport.

Accessible, easy-to-use grass catchers on the open platform

Grass catchers must be easily accessible for the operator, easy to use, and retain grass clippings both in mow and transport. The grass catcher system on the 2700 and 2750 PrecisionCut™ and E-Cut™ Hybrid Triplex Mowers delivers on all of these requirements.

Open station platform

Open station platform

An open station platform provides easy access to every grass catcher, including the rear grass catcher. All three grass catchers can be easily removed and installed with one hand, and an adjustable grab handle can be installed in a fore/aft or side-to-side orientation for the operator’s preference.

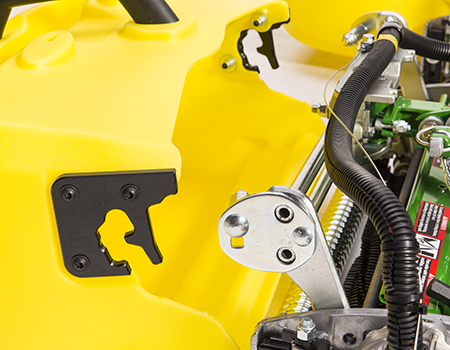

Grass catcher hook design

Grass catcher hook design

One of the challenges with grass catchers is designing them to be easy to remove and install, but without sacrificing their ability to stay on while encountering bumpy terrain in transport. An innovative hook design on the grass catchers of the 2700 and 2750 Triplex Mowers changes this from a design tradeoff to a reality. To remove the grass catcher, the operator simply pushes the grass catcher toward the operator’s station and lifts upward. Pushing in overcomes the notch in the hook and allows the grass catcher to be removed. During transport, the notch in the hook helps secure the catcher in rough terrain.

Traditional black grass catcher

Traditional black grass catcher

Translucent yellow grass catcher

Translucent yellow grass catcher

Grass catchers are offered in either translucent yellow or traditional black. The translucent yellow offers several advantages:

- The on-course supervisor can see clippings in the catcher and direct operators to empty catchers as needed.

- The operator has better visibility to clippings in catcher to know when to empty catchers.

- Catchers are easier to see in early morning and late evening conditions for better visibility of pass-to-pass overlap and edges of perimeter cuts.

Asymmetrical design and air vent

Asymmetrical design and air vent

All grass catchers feature an asymmetrical design, meaning that the left-hand side of the catcher is slightly larger than the right side. The reason for this is that due to the helical shape of the reel, the grass clippings always move to the left. In traditional grass catchers with symmetrical designs, this means that the clippings tend to pile up more in the left side of the catcher and can lower the effective height of cut on the left-hand side relative to the right-hand side, leading to step cutting as the catcher fills. This innovative design evens out the flow of clippings side to side, minimizing the opportunity for step cutting or scalping as the catcher fills up with clippings.

A deep air flow vent is molded into the top of the catcher to help make sure that clippings coming from the reel go into the catcher and stay in the catcher.

The grass catcher system on the 2700 and 2750 is an excellent blend of performance and ease of use without sacrifices.

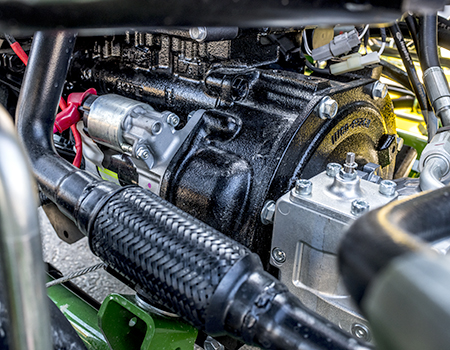

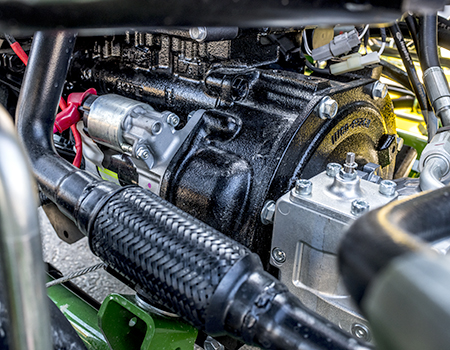

More efficiency and lower operating costs with an electronically controlled, liquid-cooled diesel engine

Electronically controlled diesel engine

Electronically controlled diesel engine

To maximize fuel economy and lower operating costs, the 2750 PrecisionCut™ and E-Cut™ Hybrid Triplex Mowers feature an electronically controlled 3-cylinder diesel engine. The engine offers 14.2 kW (19 hp) gross power (per SAE J1995 at 3000 rpm) for plenty of power while operating in a wide range of conditions, including verticutting.

In Eco mode, sensor technology automatically adapts the engine speed to the load required, improving fuel economy by delivering the precise amount of fuel required based on the load conditions encountered. The engine is liquid cooled for long life, durability, and smooth operation.

Electronically controlled pedals

Electronically controlled pedals

In combination with the electronically controlled engine, the 2700 PrecisionCut and E-Cut Hybrid Triplex Mowers also feature the AutoPedal™ system. This feature ties the ground speed and the engine speed together in transport, meaning a more car-like operation. With the foot pedal not activated, the engine will operate at idle, saving fuel. When transporting, the further the operator pushes the traction pedal, the higher the engine speed and the higher the travel speed.

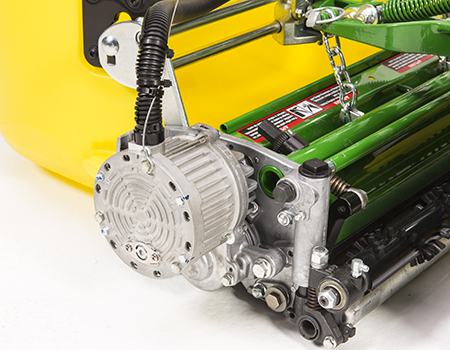

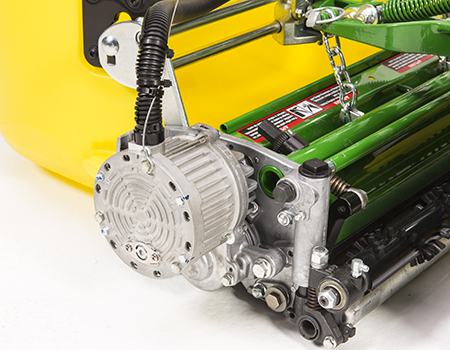

Reduce the risk of a damaging hydraulic leak with an electric reel drive system that eliminates hydraulic leak points

Electric reel motor

Electric reel motor

Ninety percent of all hydraulic leaks occur in the reel hydraulic circuit, mainly due to the necessity of having flexible hoses to power the cutting units. These hoses see a lot of flexing during the mowing day as cutting units are raised and lowered. Cutting units also steer and float to follow undulations, increasing fatigue on the reel motor hoses.

The 2700 and 2750 E-Cut™ Hybrid Triplex Mowers eliminate potential leak points by removing all hydraulics from the cutting unit drive circuit.

This hybrid design has eliminated the following hydraulic components:

- Reel drive section of hydraulic gear pump

- Hydraulic reel motors

- Mow valve

- Hydraulic oil cooler

- Flexible hoses

- Fittings

- Hard lines

Fewer hydraulic components leads to fewer leaks, increasing confidence that the finely manicured turf will not be damaged by hot hydraulic oil spilled onto a playing surface before an important tournament.

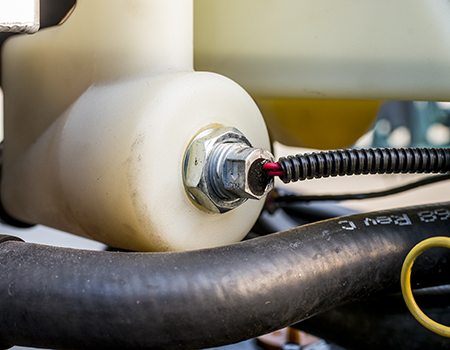

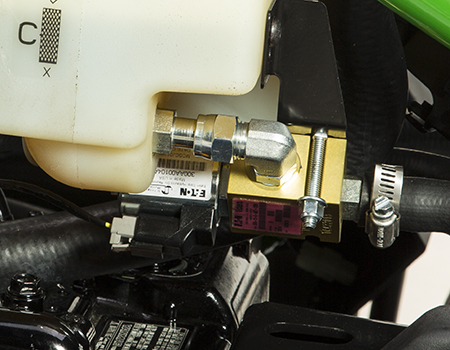

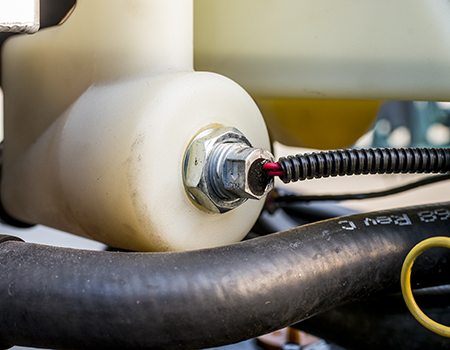

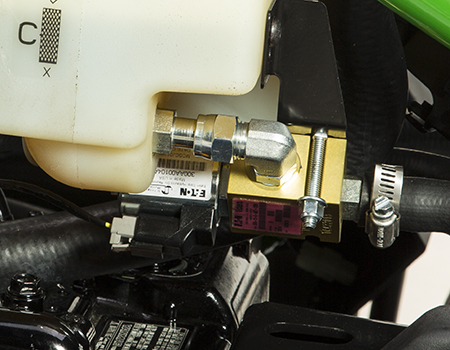

Hydraulic oil leak detector float switch

Hydraulic oil leak detector float switch

Hydraulic oil leak detector solenoid

Hydraulic oil leak detector solenoid

If a leak does happen to occur, however, an optional hydraulic oil leak detector kit is available for all 2700 and 2750 PrecisionCut™ and E-Cut Hybrid Triplex Mowers. It will alert the operator via a warning message on the TechControl display, as well as via an audible alarm. The design of the leak detector is unique in that it not only will alert the operator, but it will also disable the ability for the reels to be lowered for mowing. This limits further potential damage by not allowing the operator to continue mowing once the leak has been detected. The cutting units cannot be lowered again until the hydraulic fluid in the hydraulic tank has been filled to the proper level.

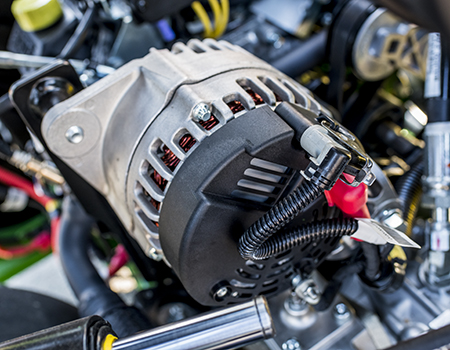

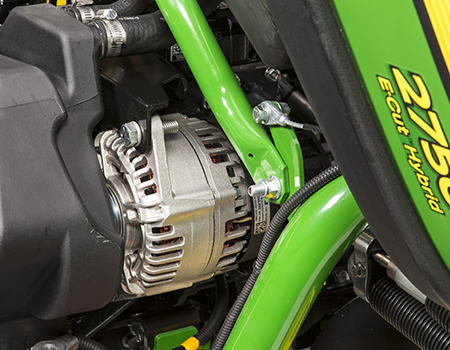

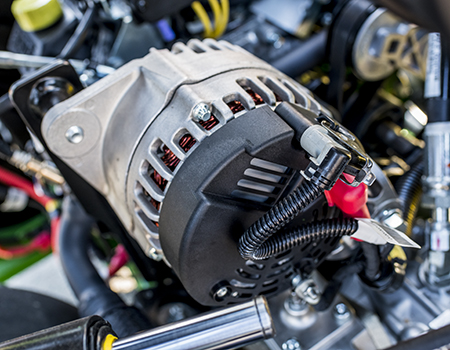

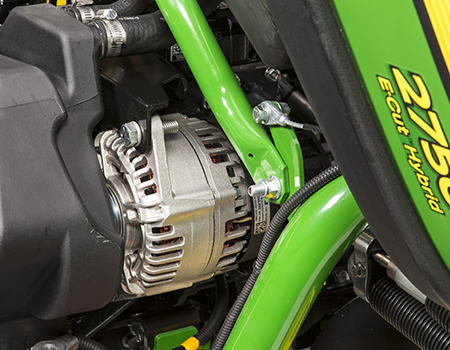

Power reel drive motors with 56-V alternator, requiring no additional batteries onboard

56-V alternator on 2700 E-Cut Hybrid Triplex Mower

56-V alternator on 2700 E-Cut Hybrid Triplex Mower

56-V alternator on 2750 E-Cut Hybrid Triplex Mower

56-V alternator on 2750 E-Cut Hybrid Triplex Mower

On the 2700 and 2750 E-Cut™ Hybrid Triplex Mowers, the reel circuit is powered by a 56-V, 100-amp alternator that is belt-driven by the engine. The alternator supplies constant power to the reel circuit and only generates the 56 V when the mow system is engaged.

Due to this design, no additional batteries are required to drive the reel motors. With traditional electrical mowing systems, performance can degrade throughout the day as the batteries lose charge during use. However, the alternator-powered design of John Deere E-Cut Hybrid reel mowers keeps performance consistent all day long.

A battery pack begins to lose its power immediately when used. Since the 2700 and 2750 E-Cut Hybrid mow system still uses an engine to power the alternator, the frequency of clip on the first green and the last green are exactly the same, yielding consistent quality of cut from start to finish.

Plus, you don't have to plug the machine in to charge the batteries once the mowing is done. The only limitation on run time is making sure the operator starts the day with a full fuel tank, just like any other gas- or diesel-powered machine on the market today.

The alternator only supplies power to the reel circuit. The remainder of the circuits are powered by the same 12-V battery used on the 2700 and 2750 PrecisionCut™ Triplex Mowers.

Minimize potential marking in turns with Turn Speed setting

Within the advanced TechControl display, you can control how fast your operators are able to turn at the end of a pass on the 2700 and 2750 PrecisionCut™ and E-Cut™ Hybrid Triplex Mowers. This feature, called Turn Speed, is a passcode-protected setting that the operator does not have access to and is adjustable independent of mowing speed.

Turn Speed in the TechControl display

Turn Speed in the TechControl display

By limiting how fast the operator can turn once the reels are raised, you can expect less opportunities for scuffing or marking in turns, improving overall aftercut appearance and turf quality. Turn Speed automatically engages and goes to the preset speed in mow when the cutting units are lifted at the end of a pass. Once the reels are lowered again to begin mowing, the speed automatically goes back to mow speed.

Typically, supervisors will want to set the turn speed to lower than the mow speed, especially on greens and other areas with tighter turns. However, for applications such as fairways where turns may be longer, you can set the turn speed to be as high as 9.7 km/h (6 mph) to increase productivity. By allowing the turn speed to be adjusted independently of mow speed, the supervisor has the flexibility to adjust for conditions, terrain, and productivity.

Turn Speed is an innovative system on the 2700 and 2750 PrecisionCut and E-Cut Hybrid Triplex Mowers that reads both wheel speed sensors. When the system detects a tight turn by seeing a large difference in speed between the outside and inside wheel motors, it automatically compensates to make the turn speed even more gentle, providing less opportunities for marking and scuffing of the turf. As with all of the other settings within the advanced TechControl display, the influence of the operator is minimized, providing better, consistent results from operator to operator.

Accurate, crisp cleanup cuts provided by innovative Cleanup Pass mode

Ask almost any operator what their biggest challenge when mowing is, and many will tell you it is accurately mowing the perimeters. It’s an area where the slightest mistake is easily seen, such as scalps from going too far into the collar or an uneven cut by staying too far inward from the edge. On many triplex mowers today, this is a challenge because the operator has to not only focus on site lines and steering, but also feathering the traction speed as most operators cannot accurately mow a perimeter at full speed. What happens is that operators want to avoid scalps, and the areas they mow tend to get smaller over time.

Cleanup Pass mode setting screen

Cleanup Pass mode setting screen

The 2700 and 2750 PrecisionCut™ and E-Cut™ Hybrid Triplex Mowers provide an innovative solution with the Cleanup Pass mode within the advanced TechControl display. The ability to set the speed is within the passcode-protected portion of the display, and the supervisor can set the specific cleanup pass speed.

Cleanup Pass mode disengaged

Cleanup Pass mode disengaged

Cleanup Pass mode engaged

Cleanup Pass mode engaged

To operate the Cleanup Pass mode, the machine must be in mow and the park brake disengaged. The language symbol will change to a drawing of a green. When the operator is ready to mow the perimeter, they simply press the button under the green symbol on the TechControl operating screen, and the machine will go to a reduced cleanup speed. This sets a new, reduced maximum mowing speed without having to feather the pedal. Once the operator completes the cleanup pass, simply lifting the reels automatically disengages Cleanup Pass mode to ensure that the next green is not mowed at a slower speed.

Cleanup Pass mode can be engaged on-the-go with the reels in either the raised or lowered position. The operator is not required to let off of the forward pedal at all. If the pedal is already pushed to its maximum mowing speed, pressing the button to engage Cleanup Pass mode automatically reduces the traction speed.

The Cleanup Pass mode can work in combination with Frequency of Clip mode, and when the two are used together, the reels automatically slow down when Cleanup Pass mode is engaged to keep the clip rate the same.

The benefit to the operator is improved ease of use. They no longer have to feather the pedal to find the right cleanup speed. Their main focus becomes steering and sight lines. The benefit to the superintendent, equipment manager, or other trusted supervisor is an improved quality of cut and improved consistency of playing surfaces regardless of the operator, as well as a nice, crisp, accurate perimeter cut.