Quick and Easy Connection

Quick and Easy Connection

Attaching the AV50 Series Root Grapple to a John Deere loader is easy with quick-change and global attaching systems. Just line up the loader's connecting points to the attachment frame and lock it in place.

AV50H (64") fits 300 & 400 Series Carrier Compatibility (JD Carriers)

AV50E (72") fits 300 & 400 Series Carriers Compatibility (JD Carriers)

AV50G (84") fits 500 & 600 Series Loader Carrier Compatibility (Global Loaders)

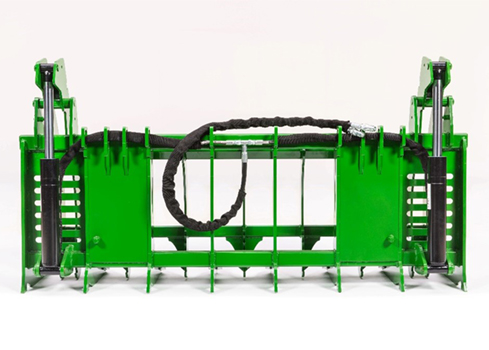

Heavy-Duty Design to Tackle Tough Jobs

Heavy-Duty Design to Tackle Tough Jobs

The AV50 Series Hydraulic Root Grapple is ideal for everything from leveling dirt and gravel to tearing up roots and moving trees. It was designed with versatility in mind, meaning the AV50 Series has the capabilities to tackle tough jobs from pushing debris to clamping or grabbing trees and limbs.

The full width design enables operators to clamp more material and improves overall weight balance since they aren’t limited to just the center of the grapple. The AV50 teeth have been designed to provide greater clamping of material without the risk of items falling out, and a push bar has been designed into the single piece top tine for pushing over small trees and repositioning brush.

The reduction in overall weight of the AV50 Series, compared to other Frontier™ grapples, has been seen to increase productivity without sacrificing loader lift capacity. With the AV50 Series you can pick up more material and utilized it on smaller tractors without compromising strength.

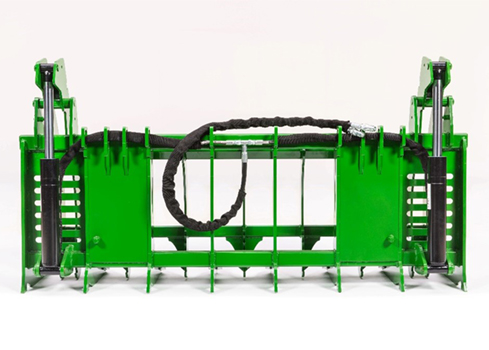

Stability for Easy Compact Storage

Stability for Easy Compact Storage

The base frame and welded feet provide the AV50 Series with a stable surface so the grapple can be easily stored in the upright position while not being used. In addition to providing stability for improved storage, the heal of the boot will aid in ripping out roots.

Hydraulics Mounted for Improved Protection

Hydraulics Mounted for Improved Protection

To provide more protection, the hydraulics have been mounted to the bottom half of the frame with the fittings that face towards the frame.