AutoTrac Vision system

Application operator using AutoTrac Vision following row crops

Application operator using AutoTrac Vision following row crops

You are accustomed to the benefits that AutoTrac provides. However, in some standing crop conditions, AutoTrac performance may be limited.

Examples include:

- Crops planted without AutoTrac

- Unavailability of guidance lines from planting

- Global positioning system (GPS) drift when using StarFire™ SF1 or SF2 corrections

- Strip-till and ridge-till conditions

In these conditions, AutoTrac Vision provides all the benefits of AutoTrac in post-emergence operations in corn, soybeans, and cotton. A monocular camera is used to detect crop rows and guide the vehicle through standing crop.

Tractor with AutoTrac Vision

Tractor with AutoTrac Vision

Hagie sprayer with AutoTrac Vision

Hagie sprayer with AutoTrac Vision

Operator benefits include:

- Reduced fatigue as manually driving in standing crop increases fatigue and mistakes

- Less crop damage due to a reduction of operator errors

- Higher speeds, thus increasing productivity. AutoTrac Vision can spray up to 20 percent faster compared to manual driving

- Increased focus on other key functions rather than focusing solely on steering

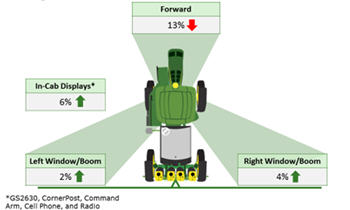

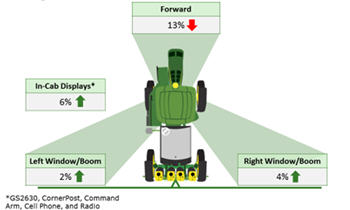

Eye-tracking study shows less time looking forward with AutoTrac Vision

Eye-tracking study shows less time looking forward with AutoTrac Vision

Results from an in-field eye-tracking study indicate that operators with AutoTrac Vision spend 13 percent less time looking forward, allowing them to focus on in-field operations instead.

AutoTrac™ Vision

AutoTrac Vision minimizes crop damage

AutoTrac Vision minimizes crop damage

AutoTrac Vision minimizes crop damage

AutoTrac Vision minimizes crop damage

When spraying in standing crop conditions, yield-limiting damage or losses can occur. As an example, some operators may choose to cross crop rows to simplify spraying and reduce stress. However, this method of spraying can damage more the 2 percent of the plants in the field. To improve yields, many operators will follow crop rows to reduce this damage. Keeping the sprayer’s wheels in between the rows ensures that plants are not damaged and reach their full yield potential.

With so much going on in the sprayer cab, a small lapse in attention can result in significant crop damage. For example, being misaligned for 1 second at 15 miles per hour could damage more than 90 corn plants or the equivalent of two bushels lost. These small mistakes add up to substantial loss over the course of a day.

The chart below shows plants damaged at a variety of operating speeds and seed population.

| Corn plants damaged per 1 second of driving misaligned at various speeds |

| Population (seeds/acre) |

19.3 km/h (12 mph) |

24.1 km/h (15 mph) |

29 km/h (18 mph) |

| 28,000 |

56 plants |

70 plants |

85 plants |

| 32,000 |

64 plants |

80 plants |

97 plants |

| 36,000 |

73 plants |

91 plants |

109 plants |

AutoTrac Vision can fall back to global positioning system (GPS) line

AutoTrac Vision can fall back to global positioning system (GPS) line

AutoTrac Vision runs again when crop is detected

AutoTrac Vision runs again when crop is detected

Not all fields are created equal. Some fields have even, clean stands while others have washouts, missing crop, or excessive weed pressure. In situations where the camera does not have confidence in the crop row due to crop stand or slope, the system reverts to GPS guidance to keep the vehicle in the row. Once the crop is detected and confidence is increased, it will revert to AutoTrac Vision.

Sprayers have the ability to run AutoTrac RowSense™ in conjunction with AutoTrac Vision when running in late-season corn. As crop begins to canopy, AutoTrac RowSense is able to “feel” the crop rows to provide accurate guidance when the camera’s vision is limited. The system uses Vision for first priority and reverts to RowSense if Vision confidence drops below the optimal range. If confidence drops below the optimal range for both AutoTrac Vision and RowSense, the system defaults to GPS using the operator’s guidance line.