John Deere Manure Constituent Sensing

Manure Constituent Sensing

- Measure liquid manure nutrient levels in real time using the HarvestLab™ 3000 sensor

- Precisely apply nutrients at targeted or limited levels with automated speed control

- Document liquid manure nutrient application to better control total crop nutrient costs

- Use nutrient application data layers in John Deere Operations Center to make better decisions

- Easily install the system on your current tanker or drag line applicator

- Get a Quote Payment Calculator

- View Product Brochure

- ShopJohn Deere

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Features

Real-time constituent measurements in liquid organic fertilizers

HarvestLab™ 3000 continuously measures nutrients during the application at more than 4000 times per second. This allows for tracking of nutrient variations between different storage locations as well as differences within individual tank loads. This data is then used to control application amounts as well as the creation of as applied documentation for each nutrient across the field. With John Deere Manure Constituent Sensing, ingredients can be applied based on a target rate for one nutrient and a limit rate for a second ingredient (i.e., target rate for N, limit rate for P).

HarvestLab 3000 utilizing near-infrared sensor (NIR) technology paired with John Deere Manure Constituent Sensing will record manure nutrient levels for total nitrogen (N), ammonium-N (NH4), phosphate (P), potassium (K) and dry matter. Tests have shown that liquid manure can be highly variable for nitrogen (N), phosphate (P) and potassium (K) between different loads with a variance factor of 4-6 for nitrogen, a factor of 10 for dry matter and a factor of 25 for phosphate.

John Deere Manure Constituent Sensing enables significant improvements in accuracy of information and application of liquid manure nutrients as compared to taking a limited number of samples per storage location or transport vehicle. The John Deere HarvestLab 3000 sensor and the respective calibration curve have been developed to deliver a higher degree of accuracy as compared to limited random samples sent to commercial labs. The NIR sensor with manure calibrations has been benchmarked against both commonly used analysis methods in laboratories (wet chemical) and NIRS lab analysis. The results indicate that the relative error for HarvestLab 3000 Manure Constituent Sensing is in the range for samples analyzed using wet chemical laboratory tests.

Ingredients/constituents which can be measured with John Deere Manure Sensing:

| Ingredients/constituents | |||||||

| Dry Matter (DM)* |

Total N | P2O5 | K2O | NH4 | Volume |

Flow rate | |

| Ingredient | X | X | X | X | X | --- | X |

| Unit send from HarvestLab 3000 sensor | Percent | lb/acre | lb/acre | lb/acre | lb/acre | --- | --- |

| Unit displayed when recording is enabled | Percent | lb/acre | lb/acre | lb/acre | lb/acre | gal./ac | gpm |

| Unit used for the GreenStar™ 3 2630/4600 CommandCenter™ /4640 Universal Display documentation | Percent | lb/acre | lb/acre | lb/acre | lb/acre | gal./ac | gpm |

* within a DM range of 2.5 – 10 percent

Speed control to ensure a consistent application

John Deere 7X30, 8X30, and 9X30 Tractors with PowerShift™ transmission and 6R, 7R, 8R, and 9R Tractors with IVT™ or e23™ transmissions equipped with Tractor Implement Automation (TIA) can achieve the desired application rate faster and more precisely than flow-based regulation only. When application conditions prevent speed control from attaining the desired application rate, tankers with flow control can also be used to attain the desired application rate.

Compatibility for TIA:

- Automated speed control is available for:

- 7X30 PowerShift John Deere Tractors

- 8X30 PowerShift John Deere Tractors

- 9X30 PowerShift John Deere Tractors

- 6R IVT and e23 Series John Deere Tractors

- 7R IVT and e23 Series John Deere Tractors

- 8R IVT and e23 Series John Deere Tractors

- 9R e23 Series John Deere Tractors

- 30 Series Tractors with PowerShift transmissions are TIA compatible. They require that the roof controller has been updated with current software to enable TIA. Once that is done, the free activation of TIA can be accessed in the StellarSupport™ portal.

- For John Deere tractors without TIA or non-John Deere tractors, manual speed control is an option.

The application rate control with automatic speed regulation through TIA plus flow control provides significant benefits compared to flow regulation only:

- Rate control through speed regulation does not have any negative influence on the distribution quality across slurry application booms or injectors.

- Rate control through speed regulation has a much faster response time.

- Rate control through speed regulation delivers a more stable regulation.

- Rate control through speed regulation is the only option possible to use with hose reel systems (umbilical).

More accurate documentation of manure applications

The John Deere Operations Center serves as the central location for contractors and farmers to connect their machines and fields. Through sharing partnerships, growers, contractors, consultants, and dealers can share valuable machine and agronomic data. This allows remote support as well as timely advanced services such as prescription creation and execution.

With John Deere Manure Constituent Sensing, the operator can determine which ingredients/values he wants to document with the GreenStar™ 3 2630 Display, 4600 CommandCenter™ Display, or 4640 Universal Display among nitrogen (N), ammonium-N (NH4), phosphate (P), potassium (K), dry matter (DM) and applied volume. These displays support up to four ingredients to be documented at the same time. As-applied maps can be uploaded manually or wirelessly with John Deere Wireless Data Transfer (WDT) into an Operations Center account. Consultants and producers can leverage the nutrient maps to calculate site-specific amounts of mineral fertilizer needed to achieve the optimum nutrient target levels.

This functionality ensures accurate documentation for compliance purpose. Application reports give users the ability to charge for manure quality rather than quantity. This information can now be used to calculate reductions of mineral fertilizer applications.

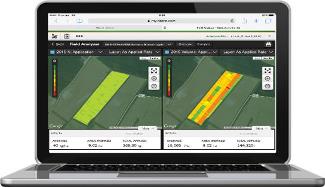

Additionally, the field analyzer lets the producer see agronomic data and provides the ability to analyze the maps created during the application. Layers can be compared side by side to make better business decisions. Data can easily be shared back and forth with trusted advisors.

Utilization of the sensor all year long

Producers can use their HarvestLab™ 3000 sensor throughout the year, leveraging the component investment for even greater value. The HarvestLab 3000 sensor can easily be moved from a slurry tanker to a forage harvester as the chopping season begins. During the forage feeding season, the system can be coupled with a stationary kit to monitor forage quality daily.

- John Deere self-propelled forage harvester (SPFH) equipped with the HarvestLab 3000 sensor:

The HarvestLab 3000 sensor allows automated length of cut adjustment based on the dry matter content, enabling better silage packing and quality. Accurate measurement and documentation of dry matter, starch, protein, acid detergent fiber (ADF), neutral detergent fiber (NDF), undigested neutral detergent fiber (uNDF), and ash allows performance tracking of different crop types and varieties. For better fertilization planning, operators can use the HarvestLab 3000 sensor to determine and document the nutrient level which was taken off the field during harvest. It also helps achieve higher quality forage and smart use of additives, which ultimately leads to higher milk yields and more efficient use of feed. - Slurry applicator equipped with the HarvestLab 3000 sensor:

The HarvestLab 3000 sensor allows precise application of liquid organic fertilizer based on target and limit rate. This eliminates over fertilization (causing laid crops) and under fertilization (causing low yields). The system allows the calculation of precise prescription maps to fill nutrient levels to the desired target; therefore, the producer pays for quality and not for quantity. Additionally, it helps to properly determine and document the applied nutrient levels to comply with legal regulations and cross compliance.

- Stationary kit and HarvestLab 3000 sensor:

The sensor utilized on a John Deere self-propelled forage harvester (SPFH) or slurry tanker can also be removed from the machine and used as a stationary unit at a storage facility or home office. The HarvestLab 3000 sensor and stationary kit can provide time and cost savings with use in the barn, field office, or anywhere wherever feed analysis is needed. For example, the total mix ratio (TMR) can be done on the farm for ease in identification of targeted ration mix.

As the solution can be used all year long and across various producer scenarios, the value generated allows for a quick return on investment.

Transforming manure from waste to valuable organic fertilizer

When manure is applied by its actual nutrient content and documented accordingly the optimum nutrient distribution and the best economic value of organic fertilizer is attained. John Deere Manure Constituent Sensing adjusts application rates to the actual field conditions and thus increases productivity (e.g., increase yield) while minimizing input cost.

The nutrient ingredients in liquid manure show high levels of variance not only between different manure types, storage locations, tank loads, but also within each of those.

The following table shows an example of the level of nutrient variability that occurs based on more than 4000 measurements per second for one tank load of hog manure.

| Ingredient | Average |

High value |

Low value |

| Dry matter | 4.0 percent | 9.5 percent | 2.0 percent |

| Ntotal | 6.0 percent | 9.1 percent | 1.6 percent |

| NH4N | 3.3 percent | 5.8 percent | 1.0 percent |

| P2O5 | 3.7 percent | 7.1 percent | 0.3 percent |

| K2O | 4.2 percent | 7.5 percent | 1.2 percent |

(Source: PDK, Netherlands 2014)

No matter how big the variability of nutrients is between tank loads/storage facilities, John Deere Manure Constituent Sensing enables a precise distribution, and maximizes the crop yield potential. This means more savings on mineral fertilization based on precise manure documentation.

Locations

- Angleton (979) 849-2325

- Conroe (936) 788-6677

- Corpus Christi (361) 452-0678

- Hockley (281) 256-6900

- Houston South (713) 943-7100

- Houston Southwest (713) 541-3535

- Jasper (409) 384-7523

- Jersey Village (713) 466-7456

- Katy (281) 391-2165

- League City (281) 338-1300

- Livingston (936) 788-5590

- Robstown (361) 387-2564

- Spring (281) 353-0204

- Hunstville (936) 788-6680

Site Map

Follow Us

Copyright © 2025 King Ranch Ag & Turf All Rights Reserved. Website by EquipmentLocator.com