John Deere 644 X-Tier Mid-Size Wheel Loader

644 X-Tier

- Net Power: 172 kW (231 hp) at 1,500 rpm

- Operating Weight: 18 856–18 892 kg (41,571–41,649 lb.)

- Bucket Capacity: 3.1–3.6 m3 (4.0–4.75 cu. yd.)

- Get a Quote Payment Calculator

- Download Payload Weighing Brochure

- Download Waste Handler Brochure

- ShopJohn Deere

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. You should obtain personal advice from qualified professionals. This information is provided for illustrative purposes only and does not constitute an application. This notice does not guarantee loan approval, nor is it an offer or commitment to make a loan to you on the above terms.

Features

Confidently hit loading targets with SmartWeigh™, John Deere’s unique payload weighing system

Loader weighing material in the bucket

Loader weighing material in the bucket

Overview

SmartWeigh™ is a John Deere designed and supported payload weighing solution that delivers accurate measurements, dynamic weighing capabilities, and is easy to calibrate. For those not sold on whether or not a payload weighing solutions is a fit for your application, John Deere offers a low cost 250-hour trial period that provides you full SmartWeigh™ capabilities to help enable you to make the decision.

Benefits

- Leading Accuracy: SmartWeigh™ provides operators with increased accuracy (+/- 1.5 percent) because of John Deere’s expertise knowledge of our loader’s kinematic properties and exact dimensions and specifications. This ensures near exact target weights are hit and efficiently loaded into feed mixers, trucks, hoppers, or processing plants. This also helps prevent the loader from having to go back to the pile to get more material or to dump excess material.

- Seamless Calibration: Unlike other payload weighing systems, SmartWeigh™ does not need to be calibrated with a known weight and is designed to be easy to complete without the help of a dealer. By going through an easy-to-follow calibration process in the machine monitor, the system will be ready to accurately weigh material.

- Dynamic Weighing: There’s no need to constantly lower and reraise the boom of the loader to determine the weight after tipping off material. Bucket capture height can be set anywhere from 15-90 percent of boom height and can be captured at any boom speed. The SmartWeigh™ system can automatically determine the new weight after tip offs, reducing the time it takes to load the exact amount of material.

- John Deere Designed and Supported: SmartWeigh™ is a John Deere designed and supported solution meaning if issues arise, the only call you need to make is to your John Deere dealer.

- JDLink™ Integrated: Integration of payload weighing data into JDLink™ means that you can access the data from nearly anywhere, not just within the cab of the machine.

- Factory and Field Kit Options: A range of options are available to equip John Deere utility loaders with SmartWeigh™ including fully integrating from the factory or adding through field kits. The 250-hour trial period enables you to utilize SmartWeigh™ for 250 machine hours and decide if you would like to easily add on the feature for the life of the machine after the trial period expires.

New technology offerings enhance operator situational awareness

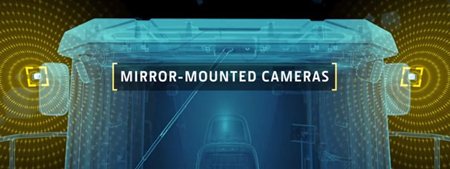

Location of digital cameras (mirror-mounted cameras)

Location of digital cameras (mirror-mounted cameras)

View of three-in-one display with dynamic reversal lines

View of three-in-one display with dynamic reversal lines

Overview

The addition of enhanced visibility and radar object detection systems improves situation awareness and can help prevent costly damage to machines and equipment. The addition of the advanced vision system and obstacle intelligence can help lower total cost of ownership and machine downtime.

Benefits

- The advance vision system integrates two digital cameras on the rearview mirror platforms and integrates those views, along with the rearview camera view located at the rear of the machine, into a dedicated single display within the cab.

- A dedicated, secondary display is larger and digital cameras provide a higher quality visual compared to analog cameras.

- Dynamic reversal projected path lines assist the operator in visualizing the anticipated reversal path of the loader based on its articulation in order to provide better line of sight to objects or people that may be directly within that path

- Lines are overlaid within the rear camera view on the dedicated monitor.

- Distinctive audible alarm notifies the operator when an object is detected with the beep speed increasing as an object comes closer to the loader.

Auto Level enables near complete parallelism and buckets and optimized Z-Bar linkage allow you to move more material and reach higher

644 X-tier loader with standard Z-Bar Linkage

644 X-tier loader with standard Z-Bar Linkage

Improved bucket rollback and material retention

Improved bucket rollback and material retention

Overview

New P and X-tier utility loaders will now be equipped with Auto Level that enables near perfect parallelism throughout the boom raise and lower cycle. In addition, enhanced performance buckets and Z-Bar linkage on P and X tier utility loaders are designed to enable loaders to be configured in a manner that allows them to be as productive as possible.

Benefits

- Auto Level can be enabled through the primary machine monitor and allows operators to set their desired attachment angle and keep that angle within +/- 2 degrees throughout the entire boom raise and lower cycle. This minimizes load rollback when using forks or buckets to improve load leveling

- Auto Level currently not available on machines configured with Tool Carrier linkage

- 8 degrees of parallelism is achieved when Auto Level is disabled

- High-Lift linkage adds an additional 305 mm (12 in.) of hinge pin height over standard linkage

- Cross tube and boom geometry design offers improved visibility to front attachments when operating and changing out between attachments during the day

- Bucket material retention has been improved by providing a 15 degree increase in bucket rollback to reduce material spillage Curved side cutters and integrated spill guards improve bucket fill rates

All day comfort in the redesigned cab

View of the newly redesigned cab from left-side entrance

View of the newly redesigned cab from left-side entrance

Additional 12V power port, USB, and Auxiliary Port

Additional 12V power port, USB, and Auxiliary Port

Rear Vent

Rear Vent

Updated sealed switch module (SSM) mounted on the right side cab post beneath the monitor

Updated sealed switch module (SSM) mounted on the right side cab post beneath the monitor

Overview

The redesigned cab in the John Deere utility loader lineup features improvements that provide the operator with a first-class work environment and a range of creature comfort options to keep them comfortable and productive no matter what task is at hand.

Benefits

- An additional 76 mm (3 in.) of leg room has been added over the previous series loaders

- Dual tilt steering column allows for dual tilt between the column and wheel to allow operators to customize the position of the steering wheel to their needs

- Additional 12 Volt power ports have been strategically placed for proper powering of devices and a USB port has been added for connecting to the radio

- Auxiliary accessory mounting points are strategically placed on the right front and rear cab posts for equipment such as a payload scale interface or CB radio

- Upgraded heating, ventilation, and air conditioning (HVAC) system to improve cooling capacity, more precise control and increased reliability and durability

- AC unit has been relocated to the right side of the cab for easier access and service

- The fresh air filter exchange is made through the top of the unit located outside the cab. This allows the dirty filter to be replaced completely outside of the operator compartment

- Brushless motor provides infinite fan speeds, quieter operation, and increased airflow

- Standard blower vent behind the seat for rear window defrost that is adjustable to control direction of air flow

- The sealed switch module has been updated and relocated on L-series and P-tier loaders. The new location brings the switches to the operator’s line of sight during operation for quick reference and ease of selection and has updated and new functions

- Selecting the About button on the main menu of the monitor, then going down to the SSM feature button the next screen takes you to a menu where you can view each button on the SSM and learn more about each feature

E-Drive enables increased productivity and unique machine features

644 X-tier in a rock quarry

644 X-tier in a rock quarry

Overview

The E-Drive delivers similar or better productivity benefits over conventional drive train machines while burning less fuel against machines in its size class and those in the next size class up. Several different features and modes assist 644 X-tier loaders with achieving this productivity across a range of jobsite applications. Whether operators are looking to control engine speed, torque, or idle, there are many John Deere exclusives and unique innovations available to deliver the best user experience.

Productivity Advantages

- The John Deere 644 X holds its own against loaders within its size class and those in the next size class up, having higher or similar productivity in common applications like Hopper Loading and Stockpiling

- The 644 X also averages a 10-13 percent fuel efficiency advantage over the competition meaning that it delivers similar or higher levels of productivity while burning less fuel

- Due to the innovative E-Drive system, the 644 X has the fastest acceleration times on both flat terrain and up a standard sloped ramp when compared to competing machines

E-Drive Features and Performance Modes

- Coast Control enables dynamic braking to slow the machine and reduce fuel consumption compared to machines without this feature. Three setting levels allow the operator to adjust the aggressiveness of machine deceleration with the use of electric brake resistors. When enabled, one pedal controls forward movement as well as dynamic braking.

- Normal Mode adjusts engine speed to match load requirements – nothing more, nothing less. Engine speed automatically adjusts up to either 1450 or 1600 RPM to meet hydraulic and tractive loads.

- Productivity Mode holds engine speed steady at either 1450 or 1600 RPM and is ready to deliver power when needed. Operator does not need to wait for RPM to increase which reduces cycle times and increases productivity compared to normal mode.

- Maintaining a constant engine speed reduces engine wear and increases fuel efficiency without sacrificing performance versus running at rated engine speed. Specifically, the 644 X-tier consumes 10 percent less fuel than the 644 P-tier model in hopper loading applications while offering similar productivity.

Additional Features

- Rimpull Control limits torque to the wheels when operating in soft or slippery conditions to minimize tire spin and slicing. It also optimizes traction when pushing into a pile to get a fuller bucket. Rimpull control settings are selected on the sealed switch module (SSM) through four increments that decrease the amount of torque to the wheels.

- Auto Idle automatically reduces engine speed when machine is not in motion and no functions are activated. Auto Shutdown shuts the machine down after a period of inactivity. Both help to lower fuel costs and save machine warranty hours.

- Throttle Lock maintains a specified rpm so the operator can warm up a machine, or road the machine without having to hold the throttle pedal down.

Increase the loader’s functionality with Electrohydraulic (EH) Controls

Built in EH controls within the right-hand joystick

Built in EH controls within the right-hand joystick

Overview

Electrohydraulic (EH) controls allow operators to customize machine operations based on preference to achieve maximum productivity across a range of jobsite applications.

Benefits

- Enable soft hydraulic stops to select how abrupt the bucket or boom stops when they reach the end of travel or when the lever of the joystick is released

- Personalize multi-function buttons 1 and 2 through 10 options within the monitor including bucket vibrate that creates a slight vibrating action for precise control when dumping specific material or EH Precision Mode that allows for fine metering of bucket or boom movement.

- Set and store up to 10 different attachment configuration settings including flow, responsiveness, and other modes through the monitor for the most frequently used attachments in your fleet.

Additional Details

| Quick Shift | EH Precision Mode |

| Horn | Bucket Vibrate |

| Soft Stop Disable | Add Truck |

| Diff Lock | Increment Counter |

| Add Bucket (if equipped) | 5th/6th Function (if equipped) |

| Aux Electrical Output (if equipped) |

Multi-Function Button Programmable Options

- Bucket Vibrate creates a slight vibrating action of the bucket for more precise control when dumping a specific amount of loose material. This is good in applications where operators need to meter loose dry material into a wagon or hopper, sprinkling rock in a pipe laying application, or for spreading an even layer of rock for road base.

- EH Precision Mode allows fine metering of bucket or boom movement when precision loader functions are required. This scales back on the aggressiveness of the functions during operation as well as limits flow. The feature is best utilized in any application that requires reduced hydraulic function speed such as laying pipe or installing manholes.

Innovative John Deere E-Drive System delivers premium performance and efficiency

E-Drive system in a 644 X-tier loader

E-Drive system in a 644 X-tier loader

E-Drive system components

E-Drive system components

What it Is

The Electric Drive system (E-Drive) is composed of a brushless electric generator and motor, power electronics (inverter), an electric brake resistor, and a simplified PowerShift™ transmission. This E-Drive system offers next level size class performance, ease of operation, and longevity to customers that invest in this innovative technology. The entire system works to dynamically adjust engine speed to meet tractive and hydraulic loads, ensuring 644 X-tier loaders can maintain stockpiles, heap hoppers, and load trucks with the highest efficiency. All of John Deere’s E-Drive components are performance proven with over 2 million field hours accumulated and counting.

How It Works

- Brushless generator converts rotational energy from the engine into 3-phase alternating current (AC) electrical energy

- AC energy is supplied to the inverter, which delivers energy to the motor based on operator demand

- Single brushless electric motor converts AC energy back to rotational energy and torque, replacing the job of a torque converter

- Simplified PowerShift™ transmission maintains smooth shifting across four operating speed ranges

- When decelerating, the electric motor can also act as a generator to recapture energy from the loader’s inertia and recycle it back into the system

- Brake resistor passively consumes excess recycled energy whenever the inverter actively controls its circuit

Why it Matters

- Electric motor doubling as a generator when decelerating reduces engine load and fuel consumption

- Electric motor turns transmission bi-directionally to switch from forward to reverse, eliminating directional control clutch pack from transmission and reducing shifting

- Brake resistor dissipates excess recaptured energy, reducing brake wear and lowering maintenance costs

- Maintaining a constant engine speed of 1600 rpm reduces engine wear and increases fuel efficiency without sacrificing performance

- The inverter constantly monitors all energy in the system and determines the most efficient path

- Brushless motor and generator provide quieter operation ideal for commercial and residential areas

Leading in sustainability through fuel and maintenance benefits

644 X-tier utility loader

644 X-tier utility loader

The 644 X-tier is the most fuel-efficient machine in its size class and in the next size class up meaning that it can move more material while burning less fuel. This allows operations to put more material through the crusher or asphalt plant while burning less fuel, providing most of its sustainability benefits. In addition, it’s design efficiencies recognize environmental impact reductions to lower carbon emissions and reduce the machine’s overall environmental impact.

- The 644 X burns up to 10 percent less fuel than competitors within its size class and up to 15 percent less fuel than competitors in the next size class up in common applications. These numbers translate into approximately 150,000 kg (330,693 lb) of CO2 that is prevented from entering the atmosphere over 15,000 machine hours, the equivalent amount of the electricity used by 11 homes over a years’ time.

- Lower volumes of oil and fluids are required when performing recommended preventative maintenance, saving up to 1,700 kg (3748 lb) of CO2 over 15,000 hours of operation compared to competitive machines. This is the equivalent of charging around 200,000 cellphones.

- Electric Drive components are designed to last in excess of 30,000 hours, meaning they can remain with the machine throughout its entire life without needing to be replaced. This extends the longevity of the machine and lowers the overall manufacturing footprint.

DRIVELINE

| Engine Manufacturer | John Deere |

|---|---|

| Engine Model | PowerTech PSS 6068 |

| Emission Rating | EPA Tier 4 / EU Stage V |

| Displacement, ltr (Inches³) | 6.8 (415) |

| Rated Speed, rpm | 1500 |

| Engine Output - Net, kW (hp) | 172 (231) |

| Torque, Nm (lbf / ft) | 1095 (808) |

| Transmission Type | Powershift w/Hybrid-Electric Drive |

| Front Differential Type | Locking |

| Rear Differential Type | Open |

| Tire size - Standard | 23.5 R25 |

| Service Brake - Type | Wet Disc |

| Service Brake - Actuation | Hydraulic |

| Parking Brake - Type | Wet Multi Disc |

DIMENSIONS

| Height - Over Cab, mm (ft/in) | 3450 (11 ft 4 in) |

|---|---|

| Wheelbase, mm (ft/in) | 3310 (10 ft 10 in) |

| Ground clearance, mm (inches) | 386 (15.2) |

| Width Over tires - Std, mm (ft/in) | 2875 (9 ft 5 in) |

| Height - Pivot Pin, mm (ft/in) | 4090 (13 ft 5 in) |

| Reach - At 2130mm 45° Dump, mm (ft/in) | 1610 (5 ft 3 in) |

CAPACITIES

| Fuel Tank, ltr (gallons (US)) | 350 (92.6) |

|---|---|

| Hydraulic Tank, ltr (gallons (US)) | 103.4 (27.3) |

| Heaped Capacity, m³ (yd³) | 3.2 (4.25) |

| Breakout - Bucket, kgf (lbf) | 15574 (34334) |

| Ride Control System | Optional |

| Pump Type | Piston |

| Pump Flow - 1, lt/min (gallons (US) / min) | 265 (70) |

| System Pressure, bar (PSI) | 251.66 (3650) |

WEIGHTS

| Operating Weight, kg (lbs) | 18856 (41571) |

|---|

Locations

- Angleton (979) 849-2325

- Conroe (936) 788-6677

- Corpus Christi (361) 452-0678

- Hockley (281) 256-6900

- Houston South (713) 943-7100

- Houston Southwest (713) 541-3535

- Jasper (409) 384-7523

- Jersey Village (713) 466-7456

- Katy (281) 391-2165

- League City (281) 338-1300

- Livingston (936) 788-5590

- Robstown (361) 387-2564

- Spring (281) 353-0204

- Hunstville (936) 788-6680

Site Map

Follow Us

Copyright © 2024 King Ranch Ag & Turf All Rights Reserved. Website by EquipmentLocator.com