Search Our Inventory: Row Crop Tractor

Search Our Inventory: John Deere 5075E

Search Our Inventory: Skid Steers

Search Our Inventory: John Deere 8370R

Search Our Inventory: Frontier Rotary Cutter

Search Our Inventory: Cotton Picker

Search Our Inventory: Lawn Mower

Search Our Inventory: John Deere Gator

Search Our Inventory: Tillage

Search Our Inventory: Zero-Turn Mower

310 P-Tier

- Net Peak Power: 75 kW (100 hp) at 1,600 rpm

- Max. Standard Dipperstick Digging Depth: 4.30 m (14 ft. 1 in.)

- Operating Weight: 6904 kg (15,221 lb.)

Features

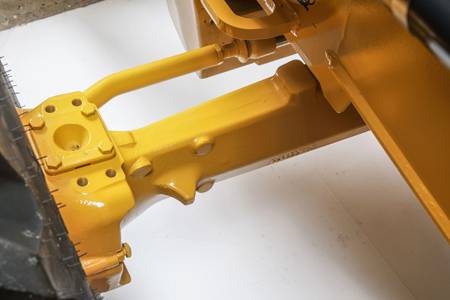

Ability to work in wet and muddy conditions

Easy to use and reliable Powershift™ transmission

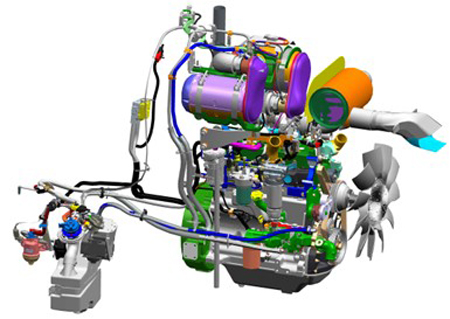

Enhanced John Deere 4.5L engine performance and reliability

Field proven and durable open center hydraulics

DRIVELINE

| Engine Manufacturer | John Deere |

|---|---|

| Engine Model | PowerTech EWL 4.5L |

| Displacement, ltr (Inches³) | 4.5 (276) |

| Rated Speed, rpm | 1600 |

| Engine Output - Net, kW (hp) | 75 (100) |

| Transmission Type | Power Shift |

| Service Brake Type | Multi Disc |

| Service Brake Actuation | Hydraulic |

DIMENSIONS

| Max length with std. Stick, mm (ft/in) | 7240 (24 ft 9 in) |

|---|---|

| Height over ext Stick, mm (ft/in) | 3390 (11 ft 1 in) |

| Width over tires, mm (ft/in) | 2200 (7 ft 3 in) |

| Wheelbase - 4WD, mm (ft/in) | 2190 (7 ft 2 in) |

| Ground Clearance, mm (inches) | 293 (12) |

| Width - General Purpose Bucket, mm (ft/in) | 2184 (7 ft 2 in) |

| Bucket Rotation - Position 1, Degrees | 190 |

| Bucket Pin Height - General Purpose, mm (ft/in) | 3480 (11 ft 5 in) |

| Dump Height - General Purpose, mm (ft/in) | 2740 (9 ft ) |

| Dump Reach - General Purpose, mm (inches) | 702 (27.7) |

| Digging Depth - General Purpose, mm (inches) | 70 (2.8) |

CAPACITIES

| Fuel Tank, ltr (gallons (US)) | 128.7 (34) |

|---|---|

| Hydraulic Tank, ltr (gallons (US)) | 45 (11.9) |

| Bucket Capacity - Standard General Purpose, m³ (yd³) | 0.77 (1) |

| Bucket Tearout - Non-Extending Dipper, kN (lbf) | 48.2 (10844) |

| Stick tearout, kN (lbf) | 31.1 (6992) |

| Bucket Breakout - General Purpose, kN (lbf) | 41.6 (9361) |

| Lift To Full Height - General Purpose Bucket, kg (lbs) | 2919 (6435) |

| Pump | Gear Pump |

WEIGHTS

| Operating Weight, kg (lbs) | 7101 (15655) |

|---|