Search Our Inventory: Row Crop Tractor

Search Our Inventory: John Deere 5075E

Search Our Inventory: Skid Steers

Search Our Inventory: John Deere 8370R

Search Our Inventory: Frontier Rotary Cutter

Search Our Inventory: Cotton Picker

Search Our Inventory: Lawn Mower

Search Our Inventory: John Deere Gator

Search Our Inventory: Tillage

Search Our Inventory: Zero-Turn Mower

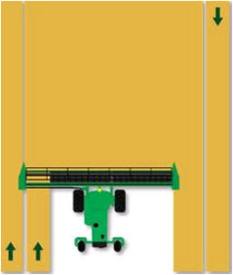

D1530

- Greater capacity to process crop with 8-inch deeper belts

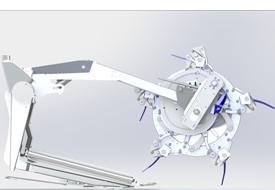

- Uninterrupted crop flow with C-shaped cutterbar

- Handle all crop conditions with strong, positive-feeding reel

- Excellent visibility to cutterbar and belt

Features

Cutterbar and frame profile gives uninterrupted crop flow

Strong, positive-feeding reel handles all crop conditions

Excellent visibility to cutterbar and belt

Gauge wheels provide ground following for uniform cut

Hydraulic deck shift gives larger windrows for more efficient harvesting

Transport easily with integrated transport system

Key Specs

| PTO speed | 540 rpm |

|---|---|

| 1000 rpm 1-3/8 in. PTO | |

| 1000 rpm 1-3/4 in. PTO | |

| Powerline type | |

| Standard hitch | Clevis |

| Optional hitch | Equal angle |

| Hydraulic pressure required | 13,790 kPa 2,000 psi |

| Cutterbar - cutting width | 2.4 m 8.1 ft |

| Number of disks/knifes | 5 10 |

| Transport width | 2.4 m 8.1 ft |

Power requirements

| PTO speed | 540 rpm 1000 rpm |

|---|---|

| 540 rpm PTO | 55-75 hp 41-56 kW |

| 1000 rpm 1-3/8 in. PTO | |

| 1000 rpm 1-3/4 in. PTO | |

| Powerline type |

Tractor equipment

| Tractor connection | 21 spline |

|---|---|

| Standard hitch | Clevis |

| Optional hitch | Equal angle |

| Hydraulic pressure required | 13,790 kPa 2,000 psi |

| Hydraulic connections |

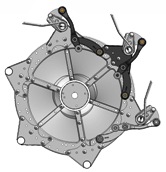

Cutterbar

| Type | John Deere |

|---|---|

| Cutting width | 2.4 m 8.1 ft |

| Cutting height | 2.8-9.8 cm 1.1-3.8 in. |

| Number of disks | 5 |

| Number of knives | 10 |

| Bolted knives | |

| Disk speed | 2,650 rpm |

| Knife tip speed | 307 km/h 191 mph |

| Disk drive | Gear |

| Lubrication | Hy-Gard oil |

| Oil reservoir capacity | 5.7 L 6 U.S. qt |

| Cutterbar oil check | Combination check, drain plug |

| Cutterbar angle | |

| Angle adjustment | Manual or hydraulic |

| Angle range | 2-8 degree (angle) |

| Cutterbar protection | ShearHub |

| Adjustable gauge shoes | Yes |

| Suspension system |

Impeller conditioner

| Width | 140 cm 55.2 in. |

|---|---|

| Diameter | 59.4 cm 23.4 in. |

| Tines type | V-tines |

| Number of tines | 33 |

| Number of speeds | Two |

| Drive | 3-V powerband belt and sheaves |

| Conditioner hood | |

| Wide spread |

Rolls conditioner

| Width | |

|---|---|

| Diameter | |

| Type of material | |

| Design | |

| Speed | |

| Drive | |

| Windrow width |

Dimensions

| Transport width | 2.4 m 8.1 ft |

|---|---|

| Overall length | |

| Transport length | 6.2 m 20.6 ft |

| Weight, roll conditioner | |

| Weight, impeller conditioner | 2,027 kg 4,470 lb |

| Standard tires | 11L-15 standard, 31x13.5L 15 optional 31x13.5L 15 optional |

General

| Are wrenches required for adjusting? |

|---|

Additional information

| Date collected | August 24, 2020 |

|---|