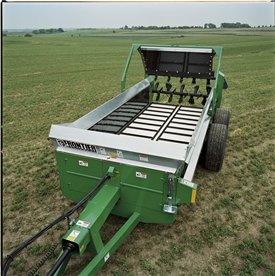

Hydraulic apron drive

Hydraulic apron drive

Two-speed apron drive

Two-speed apron drive

The hydraulic apron drive, optional on all Frontier™ heavy-duty models, provides versatile load movement with variable speeds. The two-speed apron drive includes low-speed, high-speed, and cleanout modes.

Handles large loads with ease

Handles large loads with ease

With one of the largest beaters on the market, 73.7 cm (29 in.) in diameter, the MS12 Series Spreaders cover more area from top to bottom to handle big loads with ease.

Faster tip-speed provides a wide uniform spread. Paddle assemblies match the material: blunt for wide spread patterns and sharp, ripper-type paddles for more aggressive action.

Built to ensure top-quality performance

Built to ensure top-quality performance

Spreader boxes are constructed of corrosion-resistant, galvanized steel to ensure long life.

The entire spreader box is poly-bonded to marine-type plywood for easy cleaning and minimal freeze up, reducing the amount of torque needed to move heavier loads.

End gate is perfect for high-moisture loads

End gate is perfect for high-moisture loads

The hydraulic end gate helps contain high-moisture loads and prevents spillage during transport (optional on the MS1223 and MS1227 and standard on all other heavy-duty models).

MS12 Series heavy-duty frame

MS12 Series heavy-duty frame

Frontier™ MS12 Series Spreaders feature massive all-welded frames, heavy-duty floors, and side stakes with wrap-around, steel-front corners.

Rear main beater side panels are welded to durable, 12.7-cm (5-in.), U-channel side members for extra strength and reliability.

The top beater that attaches above the rear beater provides more uniform spreading in heaped and heavily matted material. The top beater may be used with hydraulic endgate or rear pan.

Rear pan field-installation kits help to hold in loose and semi-liquid materials. The rear pan and hydraulic endgate may be used together.

For the first kit listed, the hydraulic endgate hydraulically raises and lowers to help keep loose and semi-liquid material in the spreader during transport and loading on the MS11 Series Manure Spreaders.