52-in. (132-cm) Rotary Broom on X758 Tractor

52-in. (132-cm) Rotary Broom on X758 Tractor

The 52-in. (132-cm) Rotary Broom increases tractor versatility by allowing it to be used for a variety of sweeping jobs. The broom effectively meets the needs of commercial, farm, home, and estate operators with four-season versatility:

Spring

The broom can be used to dethatch lawns, and it cleans off tennis courts quickly and effectively.

Summer

The broom effectively performs a wide variety of sweeping jobs, including cleaning sidewalks, parking lots, driveways, construction job sites, and barns. It can also be used for backfilling trenches.

Fall

The broom can be used to sweep leaves and windrow pine needles. It sweeps artificial turf and cleans up spectator areas after sporting events.

Winter

It effectively moves up to 2 in. (5 cm) of snow, which may eliminate the need for a snow thrower, depending on the operator's geographic area.

The 52-in. (132-cm ) Rotary Broom is compatible with X700 Series and 1023E, 1025R, 1026R, model year 2016 and older 2025R and 2032R, 2305-2720, 2210, 4010, 4110, 4115, and 4100 Tractors.

NOTE: If a compact utility tractor is set up for an AutoConnect™ mid-mount mower, the quick-connect drive shaft and rear lift link must be removed from the tractor before installing the rotary broom.

Polypropylene wafers

Polypropylene wafers

The 52-in. (132-cm) wide brush section is assembled with 22 convoluted polypropylene wafers.

The wafer bristles' convoluted design provides good flicking action.

Replacement wafers can be ordered from Parts:

- It is recommended all 22 wafers be replaced at the same time for even wear.

Center chain drive

Center chain drive

A center chain drive provides dependable power to the broom head:

- Large, number 50 roller chain is durable and dependable.

- Offset 3-to-1 reduction gearbox transfers power from the drive shaft to the roller chain drive.

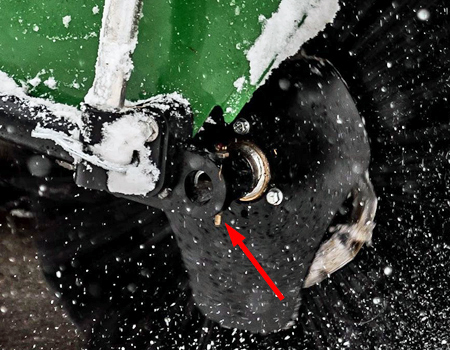

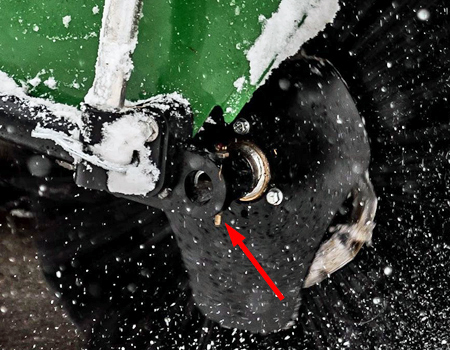

Shear bolt

Shear bolt

Shear bolts are provided at the outer ends of each half of the broom and also on the power take-off (PTO) drive shaft to protect against damage:

- Shear bolts protect the broom and drive system from damage, if an abrupt impact occurs.

- Three spare bolts for the drive shaft are provided in storage holes located at the rear of the housing.

Caster wheel

Caster wheel

Left- and right-rear caster wheels are standard equipment:

- Provide support to the brush head for optimum ground contact

- Measure 6.25 in. (16 cm) x 3.25 in. (8 cm)

- Adjustable by 2 in. (5 cm), with four 0.5-in. (1-cm) spacers

- Easy maintenance for long life through grease fittings

Precise height-adjustment knob

Precise height-adjustment knob

Adjustments are convenient and easy to make:

- Large knob allows precise height adjustment of the brush head to accommodate for brush wear.

- Chain tension adjustment is conveniently located for easy adjustment.

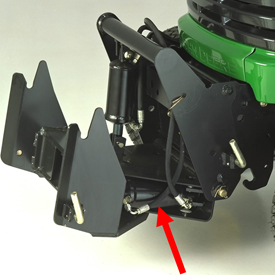

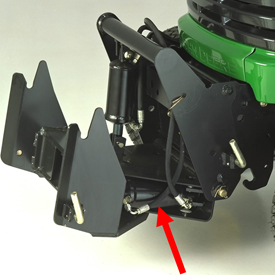

Parking stands

Parking stands

Parking stands are standard equipment:

- Help keep the broom level when hooking it up

- Keeps the broom's weight off of bristles during storage

The storage position on the mounting brackets is convenient:

- Stands are always attached to the broom to prevent loss.

- Two stands are provided for good stability.

Drive shaft support

Drive shaft support

A wire-form support is provided to position the drive shaft for easy installation of the rotary broom.

Front quick-hitch mounting system

Front quick-hitch mounting system

The broom slips over and locks into the front quick-hitch with attached snap pins:

- Fast and easy installation with no tools or loose parts

- Same hitch is used for blade, broom, snow blower, and snow thrower

NOTE: Garden tractors: The 52 Rotary Broom requires use of the newer BM19782 front quick-hitch for installation on X Series Tractors. Interference will occur if installed using a BM17347 quick-hitch.

NOTE: Compact-utility tractors:

1) 2305, 2025R, 2032R, 2320, 2520, and 2720 Tractors must be equipped with front-attaching support kit for use with the Quik-Tatch front hitch.

2) If the operator plans to use a Quik-Tatch front hitch with an OnRamp™ Mower (2025R, 2032R, 2320, 2520, 2720 only), they will need a front hitch/mid mower combo bracket to retain a tool-free change between the front hitch and the mid-mower deck.

Hydraulic-angling cylinder

Hydraulic-angling cylinder

Standard hydraulic angling allows positioning the implement straight ahead or at an angle:

- Straight ahead and infinite positions left or right

- The operator can change the angle from the tractor seat for increased productivity.

- Allows moving material off to the side and out of the way

- Allows working in a back-and-forth operation (no need to deadhead back to the origin)

- Minimizes driveline vibration in rotary broom applications, when the broom is angled

- Power take-off (PTO) shaft U-joints operate smoothly, even when the implement is angled.

Front PTO (appearance varies by tractor model)

Front PTO (appearance varies by tractor model)

The front implement is powered by the tractor's 2000-rpm front PTO:

- Engaged by the tractor's PTO clutch for smooth startups and a long life

- Easily installed and removed from tractor

- Can remain on tractor for front blade, rotary broom, and snow blower applications